|

Food pairing suggestions for King Tide DIPA from Island Brewing Company. Beer Judges (top row) Erin Peters (AKA The Beer Goddess), Lisa Wickenden (Beer Specialist for Wine Warehouse) Zachary Rosen (Certified Cicerone) and Joby Yobe (owner Barrelhouse 101)

0 Comments

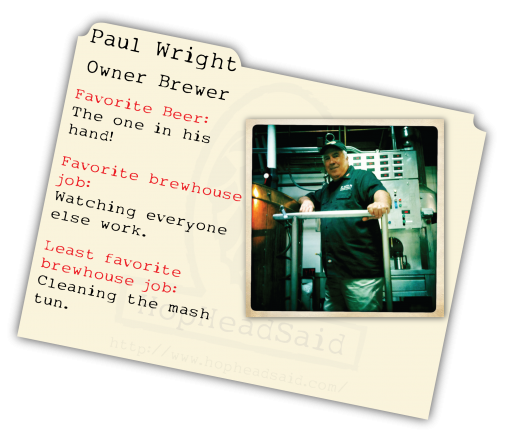

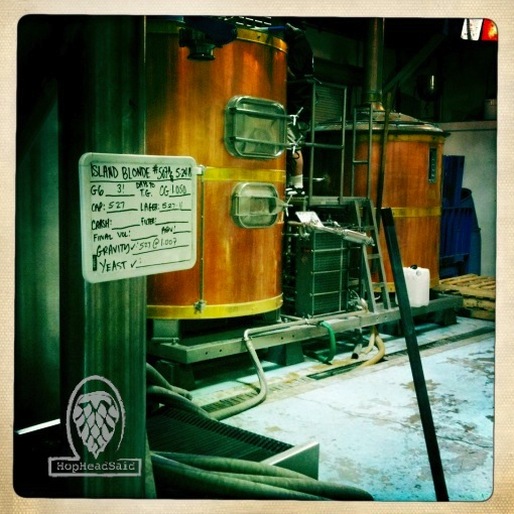

Click image to visit Island Brewing Company! In the beginning…Before there was a bourbon barrel program or Island Brewing Company or even homebrew Paul had visions of becoming a vintner. After completing his formal fermentation education at UC Davis he started making his own wine. Fortunately for the beer world he was never happy with the way his wines turned out. Then one fateful Christmas, Paul’s wife gave him a “Beer Machine” (the original can still be seen above his office in IBC’s taproom) and he never looked back. Paul joined a homebrew club, retired his Beer Machine, went all grain and became president of his homebrew club. Under his leadership and with help from its talented members, HOME (Homebrewers Of Marin and Elsewhere) became the California homebrew club of the year. Paul started volunteering and working at Marin Brewing in his spare time where he started on the ground floor, quite literally. His first jobs were cleaning the floors and kegs. He eventually moved up to kegging and bottling a couple days a week and this is where Paul added real world brewing experience to his UC Davis education. When Paul’s day job moved to Las Vegas he and his family decided moving to Sin City just wasn’t going to work for them and through a series of events (daughters attending UCSB, getting married etc.) he packed up his bags and moved to Carpinteria. It was then and there that Paul realized his dream and opened Island Brewing Company What you should know…Once a month Island Brewing Co. features one of their beers as a cask conditioned ale. What makes this so special is that one cask (7.75 gallons) of the beer is racked off the batch before it is finished fermenting into a small keg. When the beer has finished fermenting and conditioning it is tapped on a “First Friday” of each month. The beer is served much warmer and at lower carbonation levels then usual but serving the beer this way allows the malt flavors to shine through. These beers are generally consumed by the end of the weekend so be sure to check out their website so you don’t miss the next “First Friday” cask tapping. Island Brewing Co also ages some of their bigger beers (higher in alcohol and/or flavor and/or body) in bourbon barrels. The barrels they use have only been empty for only a week or two so when they get them they are full of bourbon flavor. Fresh beer is taken from the fermenter and put into the barrel where it will condition for several weeks. The beers are tasted throughout the aging process to check their progress and when they have just the right amount of bourbon flavor they are racked into a brite tank where they are conditioned and carbonated. Then the beer is bottled, hand labeled and numbered. Each batch produces around 250 bottles. Look for these bottles in their beer fridge next to the bar as they are rarely on tap. Island Brewing Co. has had much success with its bourbon barrel program. In addition to being some of my favorite BIG beers the Big Island IPA won first place at the Great American Beer Festival. Geeky brewhouse specs… Island brewing uses a tricked out 15 barrel (472 gallons) Bohemian brew system commonly found in brew pubs. The boil kettle is fitted with sensors to avoid boil overs and the mash tun has sensors to regulate water levels while mashing-in and sparging. The brewed wort is then cooled and transferred into one of the five 15 barrel fermenters. After fermentation the beer is filtered and transferred to a brite tank where the beer “rests” and carbonates before it is bottled or kegged. All of IBC’s beers are filtered to increase the shelf life of the beers. A courser filter is used on their ales to avoid stripping too much flavor out of the beer while a finer filter is used on the lager to ensure a crystal clear beer. Island Brewing Company’s official distinction has changed from production microbrewery to brewpub since more than 25% of its beer is consumed on premises. 50% of the beer IBC produces is consumed at their tap house. There are nine taps in the IBC taproom. Three of the nine taps feature a specialty or seasonal brew while the other six taps pour their regular offerings Future Plans…Paul is always looking to the future. Island brewing Co. has reached its consumption capacity and so Paul is now considering expanding off premises. He is specifically looking for a second location that would increase production and enable IBC to move into more markets like Santa Barbara.Soon Island Brewing Co. will be canning. That’s right, cans! I am especially looking forward to this because when that happens there will be no reason that I can’t have a beer at the beach. Well, almost no reason. Keep an eye on their website for their official announcement, coming soon I hope!

|

Categories

All

Archives

May 2018

|

RSS Feed

RSS Feed