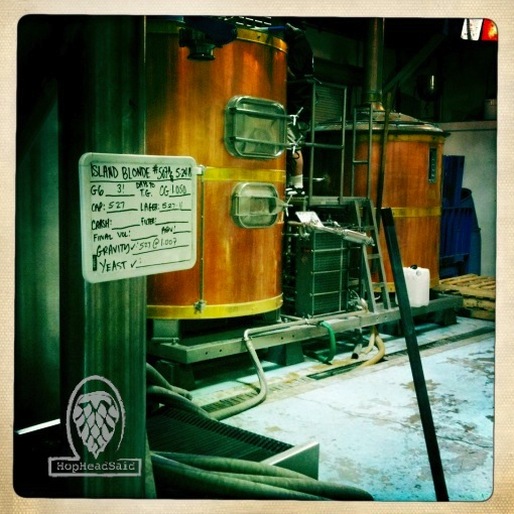

Island brewing uses a tricked out 15 barrel (472 gallons) Bohemian brew system commonly found in brew pubs. The boil kettle is fitted with sensors to avoid boil overs and the mash tun has sensors to regulate water levels while mashing-in and sparging.

The brewed wort is then cooled and transferred into one of the five 15 barrel fermenters. After fermentation the beer is filtered and transferred to a brite tank where the beer “rests” and carbonates before it is bottled or kegged. All of IBC’s beers are filtered to increase the shelf life of the beers. A courser filter is used on their ales to avoid stripping too much flavor out of the beer while a finer filter is used on the lager to ensure a crystal clear beer.

Island Brewing Company’s official distinction has changed from production microbrewery to brewpub since more than 25% of its beer is consumed on premises. 50% of the beer IBC produces is consumed at their tap house. There are nine taps in the IBC taproom. Three of the nine taps feature a specialty or seasonal brew while the other six taps pour their regular offerings

RSS Feed

RSS Feed